The vast majority of manufacturing companies in Europe are small to medium sized enterprises (SME). HPC and the technological advantages it provides are key for them to remain competitive. The Alya team at BSC has always maintained a close relationship with both big enterprises and SMEs. In the field of wind energy, the BSC team has recently been working with the company Vortex Bladeless (http://www.vortexbladeless.com). Inspired by an iconic engineering catastrophe in the USA in November 1940, Vortex Bladeless aims to harness the power of vorticity for a new generation of wind turbine.

Before the Tacoma Narrows bridge was violently ripped apart, it was extracting enormous amounts of energy from the wind. What destroyed the bridge was the vortex induced vibrations (VIV) arising from the interaction between the wind and the structure. Generally, these are natural phenomena that engineers and architects try to avoid. But for Vortex Bladeless, it formed the basis of an entirely new way of thinking about wind energy. They developed a single column with no bearings and no gears avoiding any moving parts in contact. It just oscillates with the wind.

The simplicity of the design has multiple advantages: A bladeless turbine poses no threat to birds, makes virtually no noise, costs less, lasts longer and requires less maintenance.

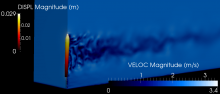

Experiments with scaled down prototypes have been encouraging, but the physics behind these devices is highly complex. In order to optimize Vortex Bladeless and explore scalability, the company has been working with a team of experts at the Barcelona Supercomputing Centre (BSC) on the MareNostrum supercomputer. The supercomputing resources were provided through 2 SHAPE PRACE projects.The fluid-structure interaction (FSI) between the Vortex Bladeless device and a turbulent flow is simulated with Alya. Obtaining the correct vortex shedding is critical for the device to work properly.

The results from initial simulations of a scaled-down device were very close to the actual wind tunnel tests performed by the Vortex Bladeless team, allowing them to develop the idea of a range of devices at the micro scale and the utility scale. Then, the behaviour of the device at a more realistic scale was studied by means of numerical simulations, helping in the design of real scale experiments and reducing costs. Due to the complexity of the flow and the need for time accurate results Large Eddy Simulation (LES) is the right choice. LES simulations are very computationally demanding and therefore if is critical to use a highly optimized code to avoid throwing away costly computational resources. Computational Fluid Dynamics simulations involve to two key operations; matrix and right hand side assembly and solving a linear system. With the help of HPC experts from the Energy Oriented Center of Excellence (EoCoE) the cpu time for assembly has been reduced up to 38%. Iterative solvers, Maphys and AGMG, provided by experts within the project have been incorporated into Alya. For some LES problems, the latter solver has provided speed ups of up to five times with respect to Alya’s own solvers. For SMEs, that are typically more limited in their resources, such savings are key to be able to use highly advanced techniques such as LES.

Videos here.